A number of national patent technologies

one-stop solution

Low purity oxygen is the first choice for on-site supply.

For providing better & swifter service, we are delighted to grant you agency and help facilitate your business with our full support.

Molecular sieve oxygen generator

MoreMore economical and energy-saving

Lower cost on oxygen production , and only electricity is used for the operation of the equipment; lower labor cost, and the intelligent control of the equipment is realized; fewer daily equipment maintenance or repair.

More Safe and Reliable

The output oxygen pressure and purity can be fully controlled. The oxygen supply continues to be stable. The backup oxygen supply system automatically starts when the oxygen pressure is insufficient or the power fails.

Simpler and Swifter

All you need to do is to turn the start/ stop button on the operation panel. Oxygen gas with required capacity and purity can be available in 30 minutes at any time.

More suitable for you

RICH technical engineers will conduct scientific analysis according to your actual situation, and design the most suitable equipment configuration plan for you.

RICH oxygen generator takes air as raw material. Being compressed by air compressor, air enters freeze dryer and multilevel filters to have its most water and impurities like dust particle removed, then flows into air tank to buffer and balance pressure before going to adsorber through switch valve, which has completed its molecular sieve regeneration and is under working state. In adsorber, gases like nitrogen and carbon dioxide are adsorbed by molecular sieve while oxygen gas enriches at the top of absorber and flows into oxygen buffer tank. After being filtrated by odor & dust removing filter and degerming filter, qualified oxygen gas is obtained.

The oxygen production of oxygen generator is a physical adsorption process, which has no chemical reaction and causes no pollution to environment. It is the ideal oxygen supply method in modernization management of practical treatment system.

The oxygen production of oxygen generator is a physical adsorption process, which has no chemical reaction and causes no pollution to environment. It is the ideal oxygen supply method in modernization management of practical treatment system.

Pressure swing adsorption (PSA), is advanced air separation technology that possesses an irreplaceable postion of on site oxygen supply in today's world.

Oxygen generator is a kind of plant that adopts pressure swing adsorption principle to generate oxygen with zeolite molecular sieve.

Under certain pressure, oxygen & nitrogen separation is realized by making use of different adsorption capacity of zeolite molecular sieve to oxygen and nitrogen in air, that is, the diffusion adsorption of zeolite molecular sieve to nitrogen is much more than it is to oxygen, pressurizing to adsorb and depressurizing to desorb.

Oxygen pressure: ≤0.6MPa (Customized)

Oxygen purity: ≥93±2%

Dew point: -60℃ (Customized)

Note: oxygen flow unit "Nm3 / h" refers to 20 ℃, average 0.101 MPa (pabs) under the state of flow unit

| Category | Oxygen yield |

|---|---|

| 20m³/h | Can be filled 40L 3 bottle per hour |

| 30m³/h | Can be filled 40L 5 bottle per hour |

| 40m³/h | Can be filled 40L 6 bottle per hour |

| 50m³/h | Can be filled 40L 8 bottle per hour |

RICH provides global hospitals with standard configuration equipment and special configuration equipment as per their different application conditions from fittings choosing to commissioning of the whole equipment. RICH persists in sustained service to ensure that the excellent quality of RICH equipment is effectively released.

Professional, Complete, Swift

1.Site Survey: Sales engineers provide all kinds of material to make objective analysis for your convenience of comparison and decision.

2.Equipment Model Choosing: Technical engineers provide customers with the best technical solution as per their actual conditions.

3.Equipment Manufacture: Technicians in Production Department make commissioning of the whole equipment before delivery to ensure its quality.

4.Equipment Maintenance: After-service engineers provide complete service mainly about malfunction prevention to ensure your safe gas supply.

5.Technical training: After-service engineers provide free professional and overall technical knowledge training of product for customers.

6.Customers visit: RICH establishes an individual archive for each equipment so as to find out the running status of equipment at any time and make detailed record. RICH will arrange visit as per the archive to help solve problems that customers meet in actual operation.

The equipped elements with famous brands effectively ensure quality of the equipment.

Efficient zeolite molecular sieves

The zeolite molecular sieve is the core of the pressure swing adsorption oxygen generator.

Reliable air supply treatment

The reliable air supply treatment method ensures the adsorption efficiency and long-term use of the molecular sieve.

The equipped elements with famous brands

The equipped elements with famous brands effectively ensure quality of the equipment.

Components ensures stably use air of system

The air tank can effectively ensures the stable air use of system. Oxygen buffer tank is to make the oxygen's pressure, purity and flow stable and empty the unqualified oxygen

The following are not part of the general functionality of the device and can be selected separately.

Automatically start& stop

Automatically start& stop the generator(can be controlled remotely).

Automatic switch to the spare oxygen

Automatic switch to the spare oxygen when malfunction or power off happen.

Friendly human-machine interface

The touch screen/industrial computer displays oxygen flow, purity, equipment inlet and outlet pressure, faults, etc.

Monitor and control the equipment at any time

Even if you are far away from the local of operation, you can monitor and control the equipment at any time.

Actuator locates inside the valve body with excellent functions such as flexible open/close,swift reaction, obvious display with feedback indication, convenient installation and maintenance, good air tightness, zero leakage. Valve seat life time is three times of the traditional ones.

The function of air tank assembly is to ensure stable system air consumption,to prevent momentary fast air flow as oxygen and nitrogen separation system switches work.Failure to do so will greatly deteriorate air cleaning effort.This assembly improves the compressed air quality entering adsorption tower and prolongs carbon molecular sieve life time.This assembly contains air tank,safety valve,check valve,ball valve,pressure meter,etc.

Load adaptation is a new concept developed by RICH in its PSA system R&D experiences.It is the achievement what RICH technical engineers obtain by many years simulation experiments and repeating demonstrations.Under the circumstance of air consumption decrease,load adaptation realizes energy consumption reduction by prolonging adsorbing circulation period and realizes extra energy-saving in typical load range.

The unique structural design can change the speed and direction of internal airflow, reduce the dead space in the tower, and improve the utilization rate of molecular sieve, which is conducive to extend the service life of molecular sieve, improve the adsorption performance of molecular sieve, and reduce energy consumption.

Simple process, compact structure, and smaller equipment investment.

It occupies a smaller area and can be used for indoor and outdoor operations.

High degree of automation, convenient and fast driving and parking.

Operation and maintenance costs are lower than the cryogenic method.

It has the characteristics of strong operation independence, good stability, high reliability, and good safety performance under normal temperature and low pressure.

The scale can be from 0.2 to 5500 Nm3/h, and the product oxygen purity can reach 25-95%.

Automatic release of unqualified nitrogen

Adapt to the load

In the event of equipment failure, power outage or insufficient gas supply, a spare nitrogen automatic replenishment and automatic switching system should be adopted

In the event of equipment failure or power failure, the backup nitrogen automaticly switches system

Remote control/Auto (dedicated)

Automatic switch, stop/restart system for filling multiple tanks

Terminal gas recovery system (specific plan and configuration)

One machine can produce more than two kinds of different purity, corresponding to different flow automatic switching system

Industrial computer, DCS

Specific solutions for specific configurations

Oxygen capacity: 1~240Nm3/h

Oxygen pressure: ≤ 0.6MPa (Customized)

Oxygen purity: 25% ~ 95%

Dew point: -60℃ (Customized)

Note: oxygen flow unit "Nm3 / h" refers to 20 ℃, average 0.101 MPa (pabs) under the state of flow unit.

Principle of Pressure Swing Adsorption Oxygen Generator

PSA, short for Pressure Swing Adsorption, is a sort of advanced air separation technology.It stands at the remarkable status in the field of on-site air supply in the world.

As shown in the chart.The zeolite molecular sieve has differ greatly in adsorption capacity for oxygen and nitrogen. There are many micro-pores in its interior. The principle of PAS is to make use of the difference between the adsorption quantities of oxygen and nitrogen in the air to reach the separation of oxygen and nitrogen in determinate pressure. When the pressure increases, the zeolite molecular sieve will adsorb nitrogen and produce oxygen. When the pressure reduces to the normal pressure, the zeolite molecular sieve will desorb nitrogen and regenerate. The pressure swing adsorption oxygen generator generally has two adsorption towers. One is used to adsorb nitrogen and produce oxygen, and the other is used to desorb oxygen and regenerate. The oxygen will be constantly produced through such alternate cycle working.

Flow Chart of Pressure Swing Adsorption Oxygen Generator

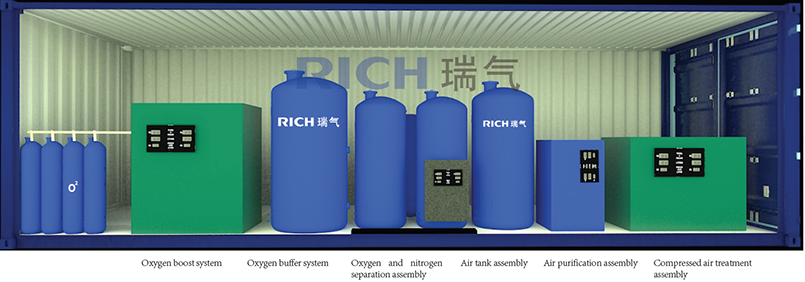

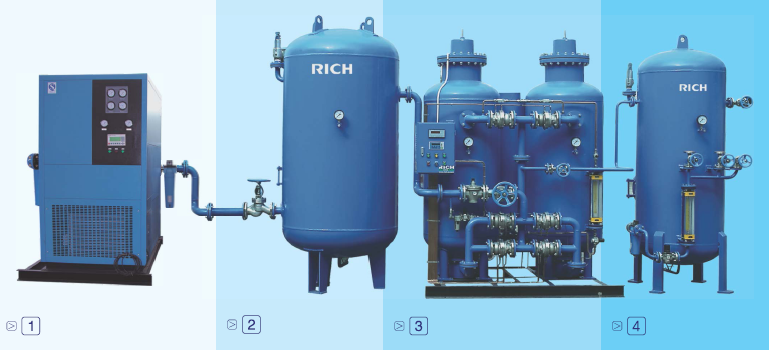

1.Compressed air treatment assembly

The compressed air from air compressor firstly enters the compressed air cleaning assembly. At first, the pipeline filter removes most of the oil, water and dust from the compressed air, and then the refrigerated drier further removes the water. The precision filter removes the oil and dust and following ultra-precision filter can deeply clean it. According to the working condition of system, RICH Company specially designs the whole set of compressed air oil removers, which can be used to avoid oil leakage and give full protection for the zeolite molecular sieve. The designed precise compressed air treatment assembly can ensure the life time of zeolite molecular sieve. The processed pure air can be used as the air for instruments.

2. Air tank assembly

The air tank is used to reduce the airflow pulsation so as to reduce pressure fluctuation of the system, make the compressed air stably enter the PSA oxygen and nitrogen separation system. At the same time, when the adsorption tower switches to the working pattern, it also will supply the PSA oxygen and nitrogen separation system with large amount of needed compressed air for rapid pressurization in a short time so as to raise the pressure in the adsorption tower to the working pressure and ensure the equipment to run stably and reliably.

3.Oxygen and nitrogen separation assembly

There are two adsorption towers A and B equipped with special zeolite molecular sieve. When the pure air enters the inlet of tower A and flows to the outlet through the zeolite molecular sieve, H2, CO2 and H2O will be adsorbed. The produced oxygen flows out from the outlet of the adsorption tower. Meanwhile, the zeolite molecular sieve in adsorption tower A will reach saturation. Tower A will automatically stop adsorbing and the compressed air will flow into tower B to adsorb nitrogen and produce oxygen and the zeolite molecular sieve in tower A will regenerate. The sieve can realize regeneration by reducing pressure of the adsorption tower to normal pressure and removing the adsorbed N2, CO2 and H2O. The two towers can adsorb and regenerate alternately so as to finish oxygen and nitrogen separation and continuously output oxygen. The above process is controlled by PLC. If purity of oxygen at the outlet is less than the set value, PLC program will work and the automatic discharge valve will open. The unqualified oxygen will be automatically emptied so that it doesn't flow to the site of oxygen utilization. You can use the silencer to reduce the noise to 85dBA when discharge the unqualified oxygen.

4.Oxygen buffer system

The oxygen buffer tank is used to equalize the pressure and purity of separated oxygen from the oxygen and nitrogen separation system so as to ensure continuous and stable oxygen supply.

Copyright@2021 Shanghai Rich Gas Technology Co. Ltd. 沪ICP备08116306号