The international brand manufacturers membrane

System integration experience

High end air purification and control system

Less investment in equipment

Standard membrane component integrated engineering design, installation fast, easy to operate, can easily achieve product gas capacity by adding membrane separator.

Less equipment maintenance

Without moving parts such as valve switching, the fault rate is very low, and the wearing parts do not need to be replaced regularly.

Quick nitrogen High purity

The device has a high degree of automation, convenient and quick to open and stop, and reaches the product gas concentration within 10 minutes; Nitrogen does not have any dust or particles. The product is clean.

High stability Strong adaptability

Strong environmental adaptability: the device has strong operational independence, good stability, high reliability, and good safety performance under ambient temperature and low pressure.

Nitrogen capacity 0.5~5000Nm3/h (20℃, 101.325kPa)

Nitrogen purity 95~99.5%

Nitrogen pressure 0.05~1.2Mpa(customized)

Dew point ≤-40℃(customized)

Control mode itellgent

Process flow and principle

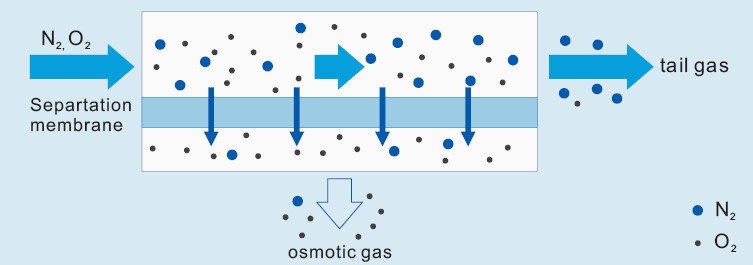

The operation of membrane systems is based on the principle of differential velocity with which various gas mixture components permeate membrane substance. The driving force in the gas separation process is the difference in partial pressures on different membrane sides .Each gas has its permeability to membrane. Due to permeability difference, when compressed air goes through the membrane units, as "fast gas", oxygen permeates through membrane walls to outside, Nitrogen as "fast gas" is collected at outlet. Higher pressure leads to high permeability of each gas, at the mean time,the efficiency drops.

In order to advance surface area of membrane and decrease the thickness of membrane makes polymer into hollow fiber. Making fasciculus consist of every supper thin hollow fiber, and then revolving to hollow fiber membrane modules-separator according to fixed separating surface. UBE super thin hollow fiber has got thinner wall and tubing, so this brings bigger specific area and higher nitrogen recovery rate to it. Inaddition, UBE super thin hollow fiber has got thinner wall and tubing, so this brings bigger specific area and higher nitrogen recovery rate to it. In addition,UBE membrane has long life, good pressure resisrance and energy saving. Comparing with other nitrogen generating membrane at the same separaring area, UBE membrane is smaller and lighter, and the capacity of air compressor used in nitrogen generation system is also smaller(better energy saving).

.png)

.png)

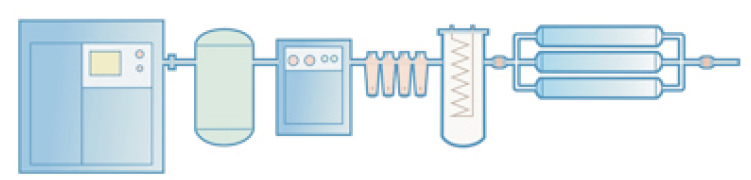

Air compressor

Hign quality screw air compressor will provide the stable and sufficient feed air quality for membrane nitrogen generator.

Air tank assembly

Buffer and reduce air pulsation, reduce system pressure fluctuation, ensure stable air passing through compressed air treatment assembly and membrane assembly. Further compressed air cooling, settlement of compressed air purification of liquid oil and water to reduce subsequent components and membrane host load.

Compressed air treatment assembly

To remove the impurities such as water, oil and dust from the compressed air, provide clean air source for membrane assembly, the rigorous air purification components design to ensure the service life of the membrane host.

Membrane assembly

Compressed air psases through membrance separator, oxygen, moisture,carbon dioxide etc. are removed and discharged to atmosphere. Produced nitrogen is generated with qualified purity, pressure and flow rate.

Copyright@2021 Shanghai Rich Gas Technology Co. Ltd. 沪ICP备08116306号