High purity nitrogen is purified

It is suitable for the purification of raw material gas with higher purity or small volume nitrogen

High reliability High stability

Equipped with self-owned advanced patented technology, advanced energy-saving process and self-made deoxygenating catalyst, the equipment is safer, more reliable and has a longer life; The device has good operation stability, high reliability, normal temperature and atmospheric pressure, good safety performance, under normal use and maintenance of 13X molecular sieve life can be more than 10 years, oxygen removal catalyst can be more than 5 years.

Patented process control valve technology

Unique programmed valve, compact structure, small space, beautiful and beautiful, switch up to 1 million failures.

Small footprint and low operating cost

The equipment has simple process, compact structure, small floor space and minimum space requirements. The unique process of parallel regeneration -- series process is adopted to solve the technical problem of desorption pollution purification gas of dissolved hydrogen after the regeneration of deoxidizer, saving about 10% gas regas emission on average.

Automatic operation Easy maintenance

High degree of automation of the device, touch screen control easy and quick start and stop, short start time, remote control of the device start and stop; The adsorber has unique structure, uniform air flow distribution and long contact time. The 13X molecular sieve is fully utilized to a large extent, and can be replaced with dehydrating desiccant or overhauled without stopping the machine

Programmable controller automation control;

Nitrogen purity and flow were monitored online;

Air conditioner and filter discharge automatically;

Spare nitrogen automatic replenishment, automatic switch;

Man-machine interface operating system;

Fault alarm, automatically shut off the hydrogenated solenoid valve;

Full automatic open stop;

Feed gas

flow rate:≤80Nm3/h

oxygen content: ≥99.9%

pressure:0.5MPa~1.0MPa

hydrogen

purity (%): ≥99%

pressure (MPa): ≥feed gas pressure+0.05MPa

Ammonia decomposition hydrogen

Oxygen content:≤10ppm

Residual ammonia:≤10ppm

Pressure:≥Feed gas pressure+0.05MPa

product gas

Flow rate: ≤60Nm3/h

Purity: ≥99.9999%

Oxygen content: ≤1ppm

hydroen content:≤1ppm (Except for hydrogen purification projects)

CO2 content: ≤1ppm

Dust particle size: ≤0.01μm

dustiness:≤1mg/m3

dew point: ≤-60℃

note:

1. For the project whose raw material gas index is out of scope, please consult our company for customization.

2. To 60 ℃ < product gas atmospheric dew point - 80 ℃ or less we can special delivery.

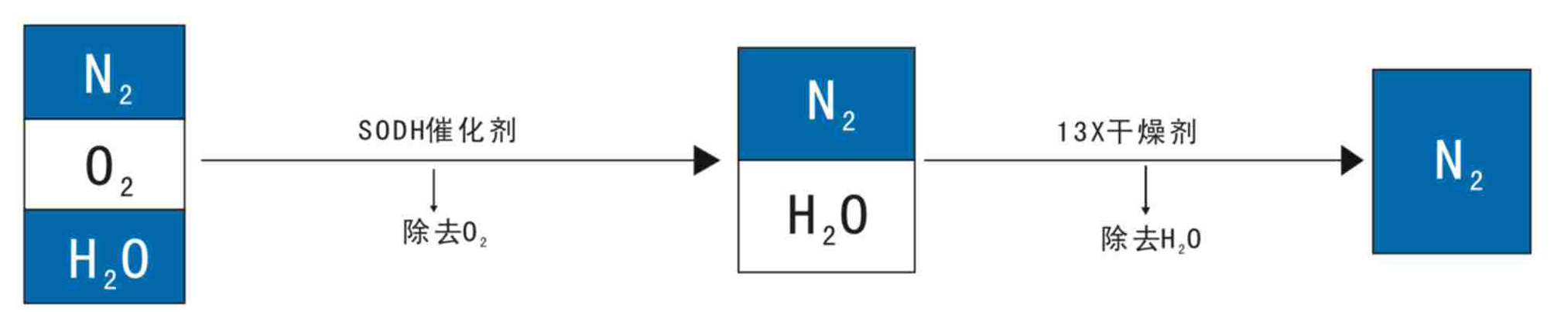

The device USES chemical absorption deoxygenation technology to remove oxygen impurities in the gas and obtain high purity gas.

It is suitable for the raw gas with purity of 99.9% or more. Generally, the waste nitrogen gas produced by the cryogenic air separation oxygen station is further deoxygenated to obtain high-purity (99.9995% ~ 99.9999%N2) nitrogen, or the cryogenic air separation nitrogen equipment is reduced in purity after years of use. Further deoxygenation purification is required to obtain high-purity nitrogen.

Due to the purification device adopts unique novel parallel regeneration - series work process, solves the due to "dissolved hydrogen" characteristics of the catalyst has caused the problem of pollution of hydrogen gas products, realize high purity oxygen and hydrogen in the gas products miscellaneous quality are less than 1 PPM of index, at the same time to achieve both energy conservation and purification operation to reduce costs, this device can also be applied to same type NCHa gas purification device of gas ranges.

NCHc nitrogen purification device consists of three parts: nitrogen pre-treatment system, adsorption drying system and electrical control system. Specific accessories are touch screen orTD200, nitrogen analyzer, flowmeter, mass flowmeter, mass flow indicator, programmable controller, deaerator, drying tower, heat exchanger, filter, pipeline pneumatic valve, solenoid valve.

.jpg)

Copyright@2021 Shanghai Rich Gas Technology Co. Ltd. 沪ICP备08116306号