High reliability, high stability, high performance

Low-cost operation

44 years of global service

Efficient field gas solution

Leading international patents

Excellent Energy-saving Features

For 40 years, we have devoted ourselves to the research and development and application of products. Compared with other nitrogen machines, our energy-saving rate is as high as 10%-30%.

Twenty years of service life

The whole machine has a design life of up to 20 years. 20 years quality assurance for pressure vessels and program controlled valves.

Reliable work

The system will automatically evacuate substandard gas to ensure the quality.

No influence to process changing conditions, and resistant various impurities.

Convenient installation and maintenance

No noise, less fault,easy maintenance.

Imported brand new hollow fiber membrane module with touch screen, fully automatic micro-computer control.

Get A Quote Now info@rich-china.com

RICH is a nitrogen generation plant manufacturer with a history of more than 40 years. Industrial nitrogen generators are widely used in various industries. Our equipment includes chemical nitrogen generators, petroleum industry nitrogen generators, laser cutting nitrogen generators, etc.With a leading nitrogen production process in China,RICH is a high-quality PSA nitrogen generator supplier and nitrogen gas plant manufacturers. We have different structures such as integrated nitrogen generator、skid-mounted nitrogen generators and mobile nitrogen generators, mobile, vehicle-mounted, etc.. Rich can provide customers with customized industrial nitrogen generator services.

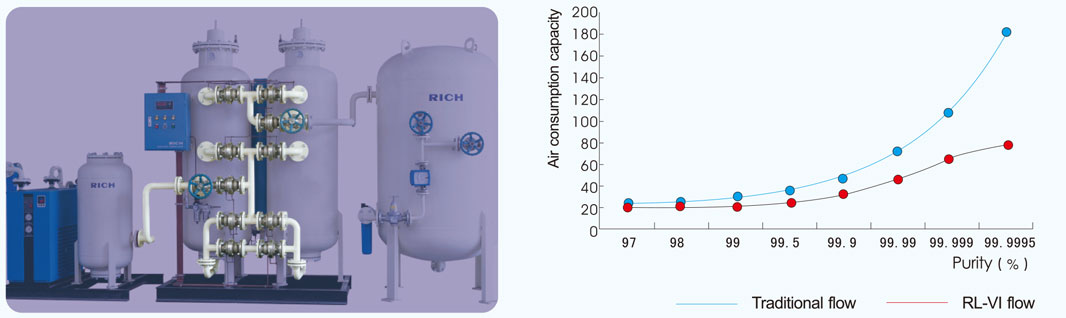

Excellent Energy-saving Features Reduce Air Usage Cost

Advanced process flow directly reduces compressed air consumption

The energy-saving CMS nitrogen gas generator provided by RICH adopts unequal pressure equalization process (RL-VI flow, patent certificate no.364126).

This process improves desorption tower nitrogen purity and reduces CMS oxygen pre-adsorption in the desorption tower and increases CMS utilization ratio, i.e,increases carbon molecular sieve nitrogen production rate. RL-VI process not only improves nitrogen recycle rate and carbon molecular sieve utilization ratio, but also changes the history that no ppm class high purity nitrogen can be produced by PSA technology.

Get A Quote Now info@rich-china.com

Nitrogen flow:5~12000 m3/h(20℃,101.325kPa)

Nitrogen purity: ≥97~99.9995%(Customizable)

Dew point: ≤-45℃(Customizable)

Nitrogen pressure:0.05~0.8Mpa (Customizable)

Nitrogen Generator with Cylinder Filling Supplier

The higher nitrogen purity,the more energy-saving

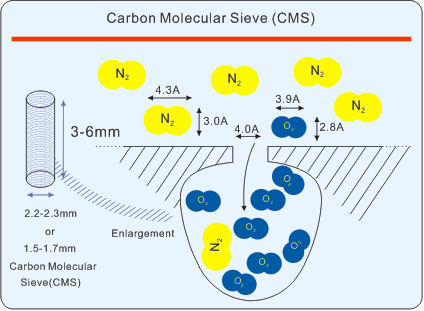

PSA Nitrogen Generator Process: clean compressed air flows inter tower A, when passing through the carbon molecular sieve, oxygen, carbon dioxide,water and other contaminants are adsorbed, allowing nitrogen flows out as product gas CMS in tower A becomes saturated as time goes by. Then tower A stops adsorption and compressed air enters tower B to adsorb oxygen and produce nitrogen. Meanwhile, CMS in tower A begins regeneration, Two towers make alternate adsorption and regeneration to separate nitrogen from air and continuously produce nitrogen.

RICH has been cooperating with world famous molecular sieve manufacturers for more than ten years. RICH can provide the most energy-saving products according to customers working condition. For some latest foreign components,RICH has obtained the sole purchase right in China.

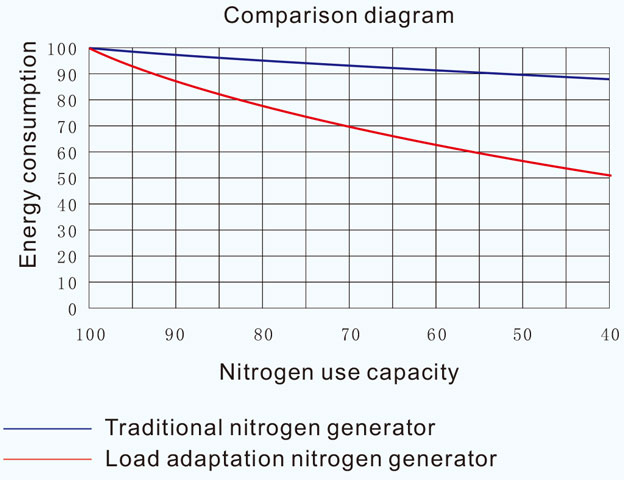

Load adaptation is a new concept developed by RICH in its PSA system R&D experiences. It is the achievement of RICH technical engineers based on many years simulation experiments and repeating demonstrations. Under the circumstance of air consumption decrease, load adaptation realizes energy consumption reduction by prolonging adsorbing circulation period and realizes extra energy-saving in typical load range.

The most reliable air cleaning process ensures adsorbing efficiency and lifetime of molecular sieve

Carbon molecular sieve(CMS) is the core in PSA nitrogen generator. Oil poisoning is one of the main reasons for carbon molecular sieve invalidation. The adsorption of water reduces CMS’s oxygen adsorption capacity. Compressed air generated by oil lubricant air compressor contains oil and water, which must be removed before it enters oxygen/nitrogen separation assembly. Air cleaning assembly consists of pipeline filter, refrigerated dryer, precise filter, super precise filter, active carbon oil eliminator, automatic drain valve and ball valve.

National patent compaction technology

Stable compacting pressure,no alteration with travel length changes. Direct travel length measurement. With sinking alarm and automatic shutdown functions. The needed air of cylinders comes directly from adsorption towers. Cylinders work synchronously with adsorption towers at any time.

Professional technologies ensure reliable gas supply

Two pneumatic valves connect with each other in series to control air source with contrary open/close state,one open,the other close.PLC judges the qualification condition of nitrogen based on nitrogen purity signal and controls the electromagnetic valve to open or close.These two electromagnetic valves control pneumatic valve switches to automatically discharge unqualified nitrogen.

Long-distance supervision and control

In control room,touching screen/industrial personal computer displays nitrogen flow and purity,pressure,fault information,etc.Equipment operating parameter modification and equipment start/shutdown control can be achieved online.

Perfect protective measures

Spare air source is suitable for areas where gas supply should not be stopped and areas with momentary high air consumption.In cases such as equipment fault,no gas supply due to power off,momentary unqualified nitrogen production,pneumatic valves automatically switch to spare nitrogen source and provide supplementary air supply.Spare nitrogen source includes nitrogen store tank,liquid nitrogen,etc.Unqualified nitrogen automatic discharge function is provided.

The following are not part of the general functionality of the device and can be selected separately.

Friendly human-machine interface

Touching screen/industrial personal computer displays nitrogen flow, purity, equipment inlet/outlet pressure and fault information.Operating parameter can be modified online

Optional functions

spare nitrogen automatic switch function in equipment, power off condition. automatic start /shutdown function(Remote control available). multiple store tanks automatic switch, shut down/re-start system function. Nitrogen generators with different purity and different flow are automatically switched, completes the function of exhaust nitrogen circulation in one machine.

Famous Compoents

famous brand compoents ensure reliable equipment quality

Load Adaptability

When the gas consumption of users is less than 100%, the gas production capacity of nitrogen production equipment is relatively rich.

The energy-saving CMS nitrogen generator provided by RICH adopts unequal pressure equalization process (RL-VI flow, patent certificate no.364126).This process changes the lower pressure equalizing position. Pressure equalizing air is gotten from the middle part of adsorption finished tower and enters the bottom part of desorption finished tower to equalize pressure.

The function of air tank assembly is to ensure stable system air consumption, to prevent momentary fast air flow as oxygen and nitrogen separation system switches work.Failure to do so will greatly deteriorate air cleaning effort.This assembly improves the quality of the compressed air that entering adsorption tower and prolongs carbon molecular sieve life time.This assembly contains air tank,safety valve,check valve,ball valve,pressure meter,etc.

Actuator locates inside the valve body with excellent functions such as flexible open/close,swift reaction, obvious display with feedback indication, convenient installation and maintenance, good air tightness, zero leakage. Valve seat life time is three times of traditional ones.

Load adaptation is a new concept developed by RICH in its PSA system R&D experiences.It is the achievement of RICH technical engineers based on many years simulation experiments and repeating demonstrations.Under the circumstance of air consumption decrease,load adaptation realizes energy consumption reduction by prolonging adsorbing circulation period and realizes extra energy-saving in typical load range.

Online monitoring of nitrogen purity, pressure and flow

Man-machine operating system

Sound and light alarm for unqualified nitrogen, long time alarm, automatic shutdown

Automatic reminder for replacement of wearing parts

Molecular sieve automatic compaction

Pneumatic valve switching is automatically controlled by PLC

Automatic drainage of cold dryer and filter

Automatic nitrogen discharge

Load adaptation

Reserve RS485 communication port or industrial Ethernet communication terminal.

Backup nitrogen automatic switching system in case of equipment failure and power cut.

Remote control/Auto (dedicated)

Multi-tank automatic switching, shutting down/restarting the system.

End gas recovery system (specific plan configuration)

One machine can produce more than two automatic switching systems with different purity and different flow rate.

IPC, DCS, other specific configuration specific configuration

Nitrogen flow:5~12000 m3/h(20℃,101.325kPa)

Nitrogen purity: ≥97~99.9995%(Customizable)

Dew point: ≤-45℃(Customizable)

Nitrogen pressure:0.05~0.8Mpa (Customizable)

PSA(Pressure Swing Adsorption)is an advanced air separation technology.It remains an irreplaceable

standing in site gas supply field.

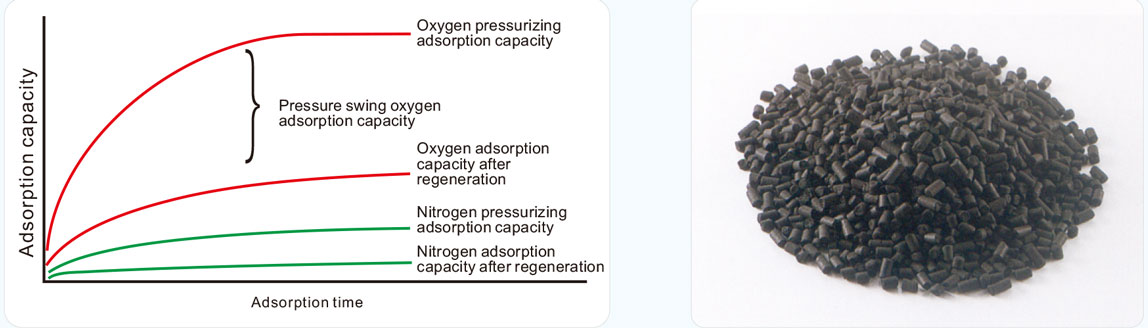

Principle of CMS Nitrogen Generation

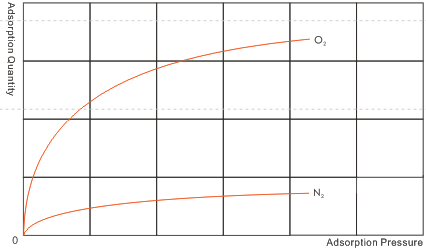

Under adsorption balance condition,for any adsorbent,when adsorbs one sort of gas,the higher the air pressure is,the more quantity it can adsorb,vice versa.

As shown on the diagram above,carbon molecular sieve has obvious adsorption differences to oxygen and nitrogen. There are many tiny holes inside the carbon molecular sieve.Under certain pressure,the tiny holes have different adsorption capacity to oxygen and nitrogen.When air pressure increases,carbon molecular sieve adsorbs oxygen and produces nitrogen,when air pressure drops to normal condition,carbon molecular sieve desorbs oxygen and regenerates itself.Two towers are generally provided,when one absorbs oxygen and produces nitrogen,the other desorbs oxygen and makes regeneration.This alternate process constantly produces nitrogen.

Main parts:filters,refrigerated-dryer,oil remover.

Functions:remove inpurities such as water, oil and dust from compressed air, provide clean air source for oxygen and nitrogen separation assembly.

Main parts:air tank and accessorial valves.

Functions:buffer and reduce air pulsation, reduce system pressure fluctuation, ensure stable air passing through air cleaning assembly.

Main parts: two adsorption towers, accessorial valves,carbon molecular sieve(CMS), cylinders and instruments.

Functions:separate nitrogen from other components in the compressed air.

Main parts : buffer tank, flow meter, pressure regulating valves, etc.

Functions : balance the pressure and purity of produced nitrogen coming from oxygen and nitrogen separation assembly,ensure stable nitrogen supply.

Copyright@2021 Shanghai Rich Gas Technology Co. Ltd. 沪ICP备08116306号